On a Singer 5 Thread Serger if the Thread in the Blue Position Keeps Breaking What Do You Do

8 things to check when the upper thread breaks

A broken upper thread means the sewing machine has failed to operate normally and is not able to sew the fabrics firmly. If you have found that the upper thread breaks, you can check the machine if any of the following has happened and fix the issue accordingly:

The machine is not threaded correctly

When not threaded correctly, the thread undergoes great tension or forms knots when sewing. Unthread and re-thread the machine according to the instruction manual. While there is slight differences of threading process among different models, make sure you thread the machine with the presser foot lifter raised, the needle raised and at the highest position.The thread should pass through all the parts of the thread guide, the hook pin in front of the needle and then thread into the needle. The bobbin thread should also be brought up. Check out the details of threading the machine here.

The thread should pass through all parts of thread guide and take-up lever.

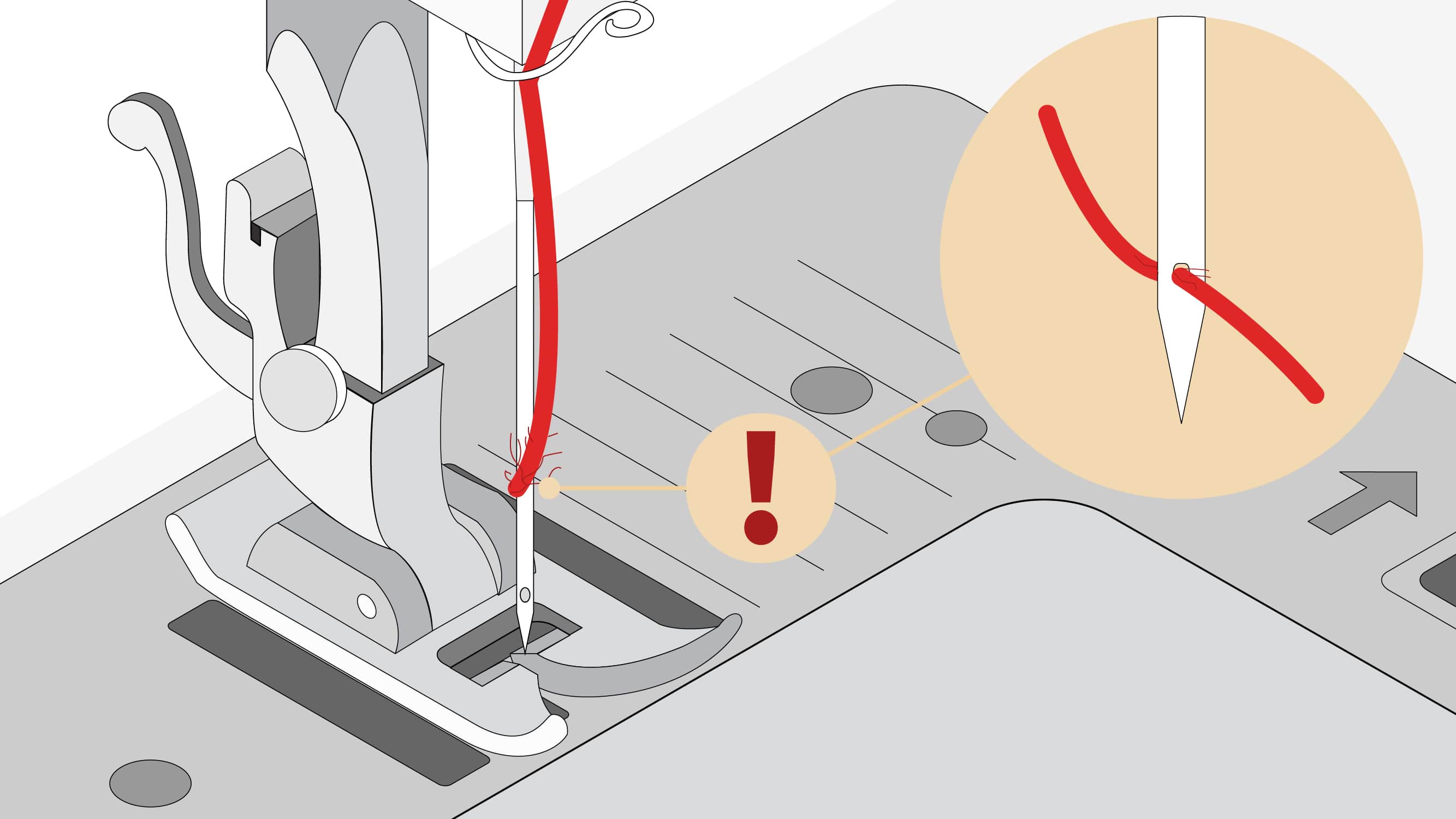

The thread forms loops around the needle

Sometimes if not paying full attention when threading, the upper thread may form loops around the needle, which leads to broken thread when sewing. You need to re-thread the needle. Keep in mind that the thread should pass through the needle eye from the front to back. There should not be any thread loops and knots around the needle.

If the upper thread forms loops around the needle, it may be broken by the needle when sewing

The thread tension is too tight

When the tension is set too high, the thread is stretched greatly from the spool to the needle, causing great tension in the thread and thus the upper thread breaks during sewing. You can reduce the thread tension to see if it improves. A lower number indicates a lower level of tension.

Working with a suitable tension can prevent upper thread from breaking when sewing.

High needle temperature

This affects specifically synthetic threads. A high needle temperature may make the thread fuse or break due to the thermoplastic property. Applying thread lubricant can avoid the thread from breaking.

High needle temperature may make some polyester thread fuse or break.

The thread is too thick for the needle

When the thread is too thick, it does not fit the eye of a smaller size needle well. This causes great friction built up between the thread and the eye of the needle and breaks the thread. If you need to use thick threads, choose a larger size needle.

When the thread is too thick for the needle, excessive friction builds up between the thread and the needle eye, making the thread break.

The needle is not inserted correctly

If there is still space in the needle shaft, or if the flat side of the needle faces you, the thread will break easily. You can try to remove and re-insert the needle, with the flat side always towards the back and no space left in the needle shaft.

When inserting the needle, the flat side of the needle should be facing the back. Do not let any space left in the shaft.

The thread winds around the spool holder pin

With a thread winding around the spool holder pin instead of its reel, the thread is put under great strain when sewing and eventually breaks. You will need to clean up any thread left in the holder pin, so that the thread can come out from the reel smoothly.

If the thread winds around the spool holder pin, clean it up to let thread come out from the reel smoothly.

The needle is damaged

A damaged needle is not able to hold the thread well. When sewing, it causes great friction against the thread, making it break. If there is any damage in the needle, replace it with a new one.

If the needle is blunt, bent or any other sign of damage, replace it with a new one.

Source: https://singer.com.hk/blogs/sewing-tutorials/8-reasons-the-upper-thread-breaks

0 Response to "On a Singer 5 Thread Serger if the Thread in the Blue Position Keeps Breaking What Do You Do"

Post a Comment